Crank Charger, Crank-Powered Tools, and Black Granite

The final part of this age will require obtaining black granite, a material which spawns in the nether. However there are a couple of things to do before you can harvest it.

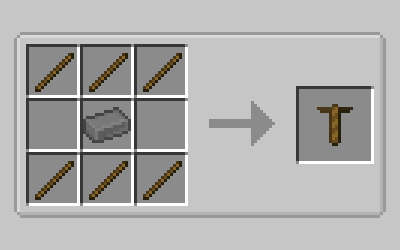

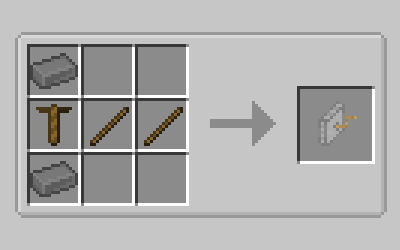

The first will be the creation of a Crank Charger and Crank-Powered Tools (of which you will only need the crank-powered pickaxe), which will be needed in order to successfully harvest the Black Granite.

Note

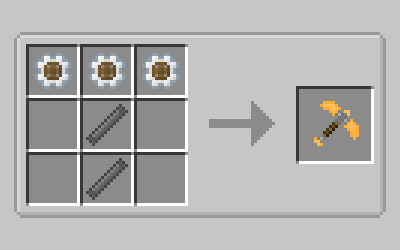

Crank-Powered tools are created exactly the same as their vanilla counterparts (exactly like the titanium hammer, for the hammer variant) with the exception of using either Gold or Titanium gears as the material and Steel Rods as the sticks. Note that it must be either Gold or Titanium gears, I used titanium in this example as it is less resource intensive than gold. Obtaining the plates and gears is the same as above, as well as the creation of pure titanium.

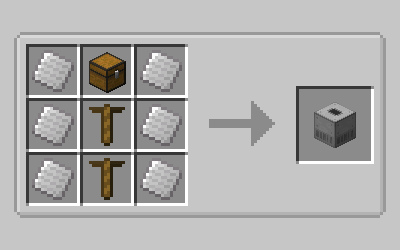

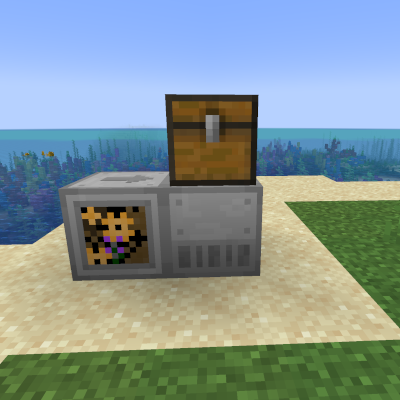

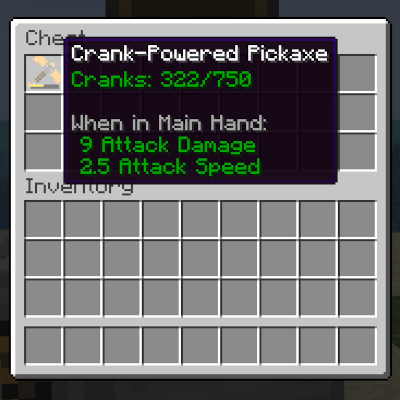

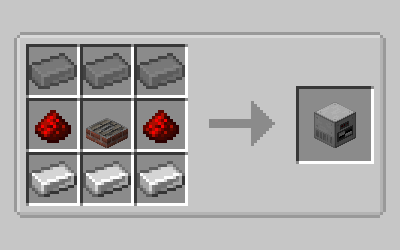

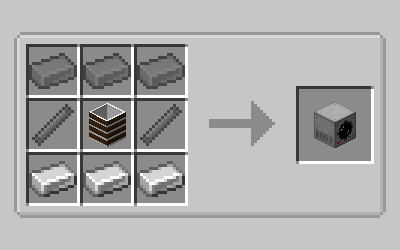

Crank-Powered Tools as their name suggests, uses cranks to break blocks and deal damage, every crank tool has an internal storage of 750 cranks of which it will consume 1 crank per operation (breaking a block, dealing damage) which can be recharged using the crank charger. Storing cranks in the tools using a crank charger is done by building a multiblock which should look like this when constructed successfully.

Simply put your crank tools in the inventory above the crank charger and supply crank power to the charger itself (only through a gearbox) and it will start to store cranks within the tool, starting from first on the left and ending at the last to the right, top to bottom.

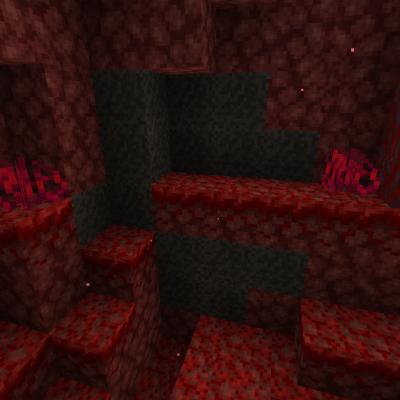

With your fully charged crank pickaxe in hand your next task is to find black granite in the nether! Black granite spawns anywhere in netherrack in large veins (pictured below).

With black granite obtained you’ve reached the end of the Crank-Age and the dawn of the Electricity-Age!

Is there a catch?

Lifting, cutting, chopping, moving, bending—machines like the ones we’ve explored up above make it easier to do all kinds of things

by making forces bigger than you can normally create with your own body. At first sight,

that sounds like it might open up the way to designing a machine that can give us something for nothing—maybe one

that can make energy out of thin air, or a perpetual motion machine that runs forever.

In practice, the laws of physics are strict and if you make life easier for yourself in one way,

you always make it harder in another to compensate. That’s the scientist’s way of saying “there’s no such thing as a

free lunch,” and, in physics, it goes by the name of the law of conservation of energy

(simply put: we can’t make energy appear magically out of nowhere).

So whenever you have a machine that gives you more force, it doesn’t give you extra energy you didn’t have before.

With a pulley, for example, ropes and wheels give you much more lifting force, but you have to heave them much further,

so you use exactly the same amount of energy as you would have done before. You just use it more slowly, with less effort,

so the lifting feels easier. In the same way, you can use a see-saw to lift a much heavier friend by sitting further

from the balancing point than they are, but you have to move your legs much further to compensate. You get extra force, but

no extra energy—and that’s the catch.

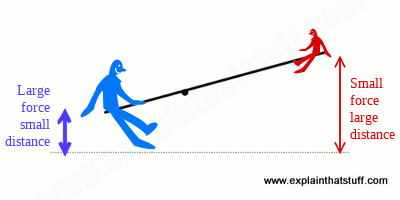

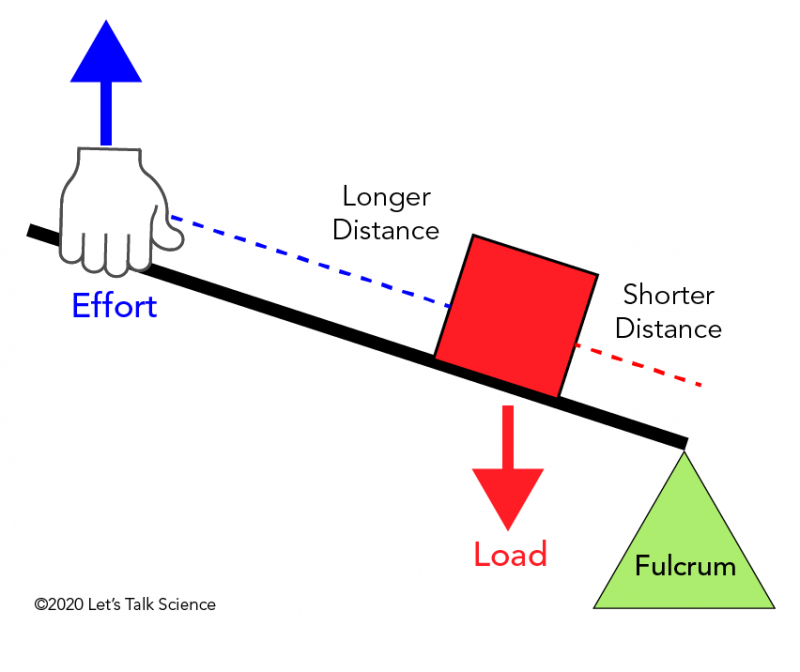

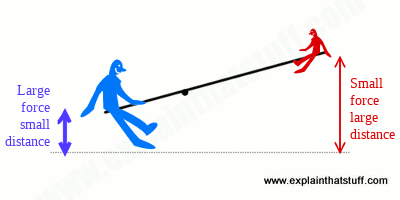

Artwork: A seesaw lets you create extra lifting force. The little red person

can lift the big blue person by sitting further from the pivot point. That means they can lift a bigger force, but

the catch is that they have to move their own body over a much bigger distance.

This machine makes more force, but no more energy.

Simple Grinder and Crank Power

The first thing you’ll want to do is upgrade your fluid bath and manual grindstone into their simple variants. Starting off with the Simple Grinder!

There’s still a bit to do before your grinder is ready to use, because every machine in this age requires crank power, the next thing you’ll want to craft is a crank!

With the crank acquired you’re ready to start using the simple grinder. First place down the simple grinder, because simple machines do not have an internal output slot you’ll want to place a chest (or any valid storage entity) on the right-hand side to store any output items you create. Afterwards simply SHIFT+RIGHT-CLICK with the crank in your main hand on any other available side of the simple grinder to attach it, the full multiblock should look something like this.

Be careful!

The output inventory has to be on the right-hand side of the machine or it will not output.

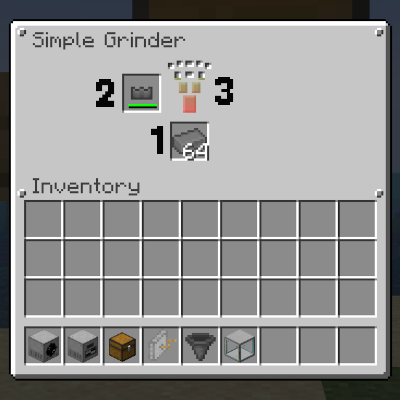

Once you’ve made the simple multiblock structure you’re ready to start grinding. Thankfully the GUI’s fairly straight forward so we’ll run through that quickly.

Input slot for the Simple Grinder

Blade slot (Note that the simple grinder will still consume durability on blades while you process recipes)

Progress bar (once this fills up the output will be pushed to the inventory on its right)

Once you’ve put in a valid recipe you’ll want to start processing it. To do this just hold RIGHT-CLICK on the crank you attached, the crank should start emitting particles and the machine should start its processing animation.

Be careful!

If you try to power the machine with a crank while no valid recipe is within its input slot, or the output slot is full; then there’s a chance that your crank may break with every RIGHT-CLICK dropping sticks and steel-nuggets.

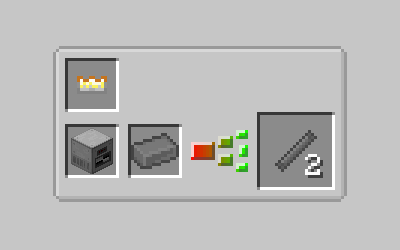

The first recipe you’ll want to make with the simple grinder is steel rods, which can then be crafted into the Simple Fluid Mixer.

Note

This recipe can only be made in the simple grinder, using a manual grindstone will not work.

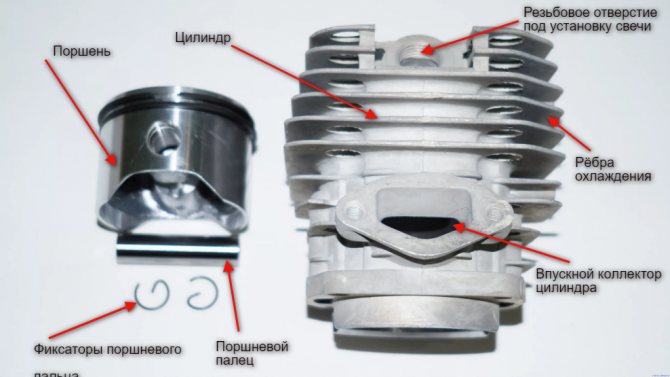

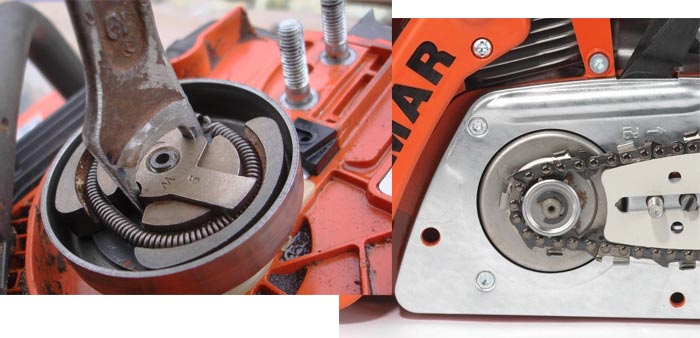

Почему именно эта модель?

На момент покупки отзывов о продукции этого бренда практически не было. Информации о том сколько в киловаттах будет аналогом мощности двухтактного двигателя также не обладаю. Да и невозможно так сравнивать, поскольку крутящий момент пилы зависит не только от мотора, но и от конструкции редуктора, диаметра вала, количества зубьев на звёздочке и т.д.

У меня есть личное отношение к определению ценового диапазона. Если бы я работал профессиональным заготовителем дров, то выбирал бы товар из категории “дороже, но надёжнее”. Но если инструментом не предполагается пользоваться каждый день, по восемь часов в сутки, круглый год, то не вижу смысла переплачивать за “супер надёжность”. В случае с домашней заготовкой дров это увеличивает стоимость продукции, и снижает рентабельность.

В итоге при выборе модели sterwins 2000, опирался на длину шины, на количество киловатт (необходимо чтобы розетка, электроавтомат, сечение проводов, выдерживали требуемые нагрузки). Также меня подкупил тройной срок гарантийного ремонта. Конечно, магазины Леруа находятся на изрядном удалении от хозяйства, но как мне кажется, в совокупности это наиболее подходящее предложение. Качество конкретного инструмента — лотерея. Можно с одинаковым успехом купить постоянно ломающееся устройство за большие деньги, и надёжный инструмент за небольшую сумму. С этим не угадаешь и заранее результат лотереи не узнаешь.

Gears

Photo: A gear is made from two or more wheels of different sizes with teeth cut into their edges to ensure they “mesh” (turn together without slipping).

Gears are wheels with teeth that can either increase the speed of a machine or its force,

but not both at the same time. Bicycles use gears in both ways. If you want to pedal up a hill,

you use gears to increase your force so you don’t have to work quite so hard, although the

catch is that they reduce your speed at the same time. If you’re racing along a straight road, you can use gears to increase your speed, but this time the catch is that they’ll reduce your force. Although it’s not obvious just by looking

at them, gears work in exactly the same way as levers (just as wheels do).

That takes quite a bit of explaining so we won’t go into more details here.

Instead, you can read all about it in our gears article.

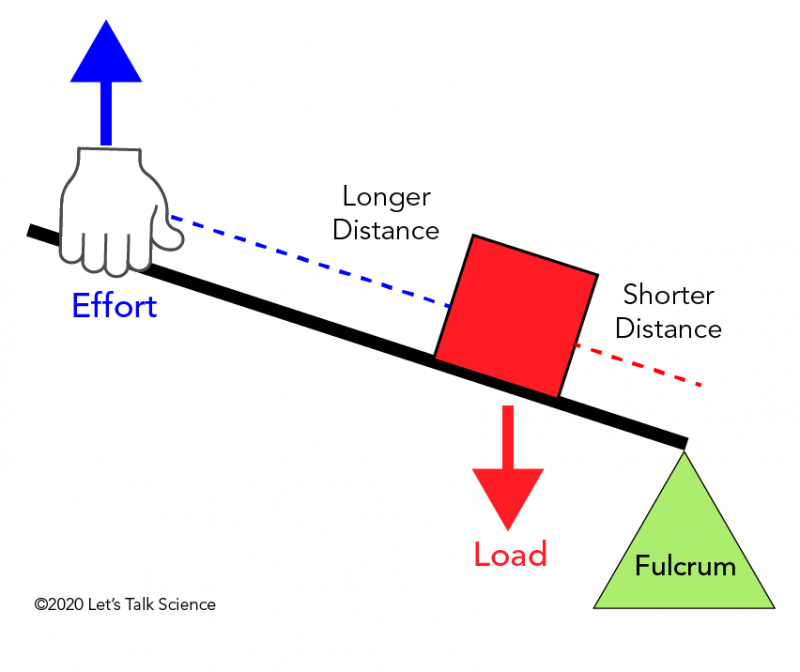

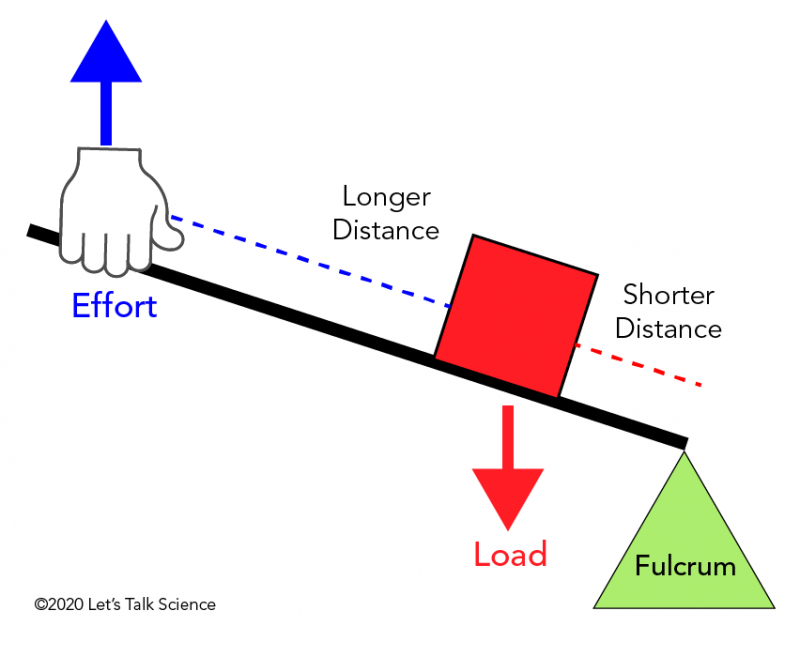

Second Class Levers

In a second class lever, the load is located between the effort and the fulcrum.

In a second class lever, the load is located between the effort and the fulcrum. When the fulcrum is closer to the load, then less effort is needed to move the load (2020 Let’s Talk Science).

In a second class lever, the load is located between the effort and the fulcrum. When the fulcrum is closer to the load, then less effort is needed to move the load (2020 Let’s Talk Science).

If the load is closer to the fulcrum than the effort, then less effort will be required to move the load. If the load is closer to the effort than the fulcrum, then more effort will be required to move the load. A wheelbarrow, a bottle opener, and an oar are examples of second class levers.

Second class levers are used in wheelbarrows (left), when going on tiptoes (centre) and when doing push-ups (Sources: MarkusHagenlocher via Wikimedia Commons, BruceBlaus via Wikimedia Commons and U.S. Navy via Wikimedia Commons).

Second class levers are used in wheelbarrows (left), when going on tiptoes (centre) and when doing push-ups (Sources: MarkusHagenlocher via Wikimedia Commons, BruceBlaus via Wikimedia Commons and U.S. Navy via Wikimedia Commons).

Simple Machine Projects

Ready to make a simple machine project? We have so many fun simple machines projects ideas using simple items from around your house or classroom.

- Archimedes Screw Exploration from High Hill Education is a simple project using a plastic bottle that showcases how this invention made hundreds of years ago was able to move material.

- Kids will get a kick out of moving toys from downstairs to upstairs using this Banister Pulley from Hands on As We Grow

- Kids are sure to be impressed by this working elevator model that explores pulleys from How to Adult

- Let your kids imaginations run wild as they make their own Button Wheel & Axel Cars from Almost Unschoolers

- This Corn Pulley from Play at Home Mom LLC is just what your preschooler needs in their sandbox to make simple machines come alive

- Pulley Experiment for Kids from 123 Homeschool 4 Me uses common household items like cans to make a fun-to-try simple machine

- No time to make your own simple machine, no worries! Do what Exploring Forces & Motion from A Day in First Grade did

- Simple machines and art collide in this fun Inclined Planes Art from Strong Start

- Explore the usefulness of Inclined Planes in this “Egg”speriment from 123 Homeschool 4 Me

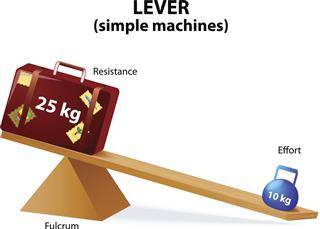

Lever

This boastful claim is attributed to the third-century Greek philosopher, mathematician and inventor Archimedes. While it may be a bit of an exaggeration, it does express the power of leverage, which, at least figuratively, moves the world.

The genius of Archimedes was to realize that in order to accomplish the same amount or work, one could make a trade-off between force and distance using a lever. His Law of the Lever states, “Magnitudes are in equilibrium at distances reciprocally proportional to their weights,” according to “Archimedes in the 21st Century,” a virtual book by Chris Rorres at New York University.

The lever consists of a long beam and a fulcrum, or pivot. The mechanical advantage of the lever depends on the ratio of the lengths of the beam on either side of the fulcrum.

For example, say we want to lift a 100-lb. (45 kilograms) weight 2 feet (61 centimeters) off the ground. We can exert 100 lbs. of force on the weight in the upward direction for a distance of 2 feet , and we have done 200 pound-feet (271 Newton-meters) of work. However, if we were to use a 30-foot (9 m) lever with one end under the weight and a 1-foot (30.5 cm) fulcrum placed under the beam 10 feet (3 m) from the weight, we would only have to push down on the other end with 50 lbs. (23 kg) of force to lift the weight. However, we would have to push the end of the lever down 4 feet (1.2 m) in order to lift the weight 2 feet. We have made a trade-off in which we doubled the distance we had to move the lever, but we decreased the needed force by half in order to do the same amount of work.

What is a machine?

To do anything at all—to lift a box, to push a car, to get out of

bed, to jump in the air, to brush your teeth—you need to use a pushing

or pulling action called a force. If you go around telling

people you’re strong, what you really mean is that your body can apply a lot of force. You

may have watched incredibly strong people on TV pulling trucks or

trains with their bare hands, but there’s a limit to what even the most

muscle-bound human body can do. Simple machines let us go beyond that

limit. Simple machines can make us all strong!

Photo: Thumbtacks (sometimes called drawing pins) are a bit like nails with built-in hammers. When you push on the large, flattened head, the force you apply (to the large flattened end) is effectively magnified because it’s

concentrated into a much smaller area at the tiny pin head. According to science, even thumbtacks are simple machines.

When you hear the word “machine”, you probably think of something

like a bulldozer or a steam locomotive.

But in science, a machine is

anything that makes a force bigger. So a hammer is a machine. A knife

and fork are a pair of machines. And even an egg whisk is a machine.

All these machines have one thing in common: when you apply a force to

them, they increase its size and apply a greater force somewhere else.

You can’t cut meat with your hand alone, but if you push down on a

knife, the long handle and the sharpened blade magnify the force you

apply with your hand—and the meat slices effortlessly.

When you pound a nail with a hammer, the handle increases the force you

apply. And because the head of the hammer is bigger than the head of the nail,

the force you apply is exerted over a smaller area with much greater

pressure—and the nail easily enters the wood. Try pushing in a nail with your finger and

you’ll appreciate the advantage a hammer gives you.

There are five main types of simple machine: levers, wheels and axles (which count as one),

pulleys, ramps and wedges (which also count as one), and screws. Let’s look at them more closely.

Inclined Planes

An inclined plane is exactly what its name says. It’s a plane that is inclined, or in other words, slanted. This simple machine connects a lower level to a higher level, making it easy to move objects. The slanting surface supports some weight of an object as it moving upwards, making it utilize less force. However, the object must move at a longer distance than it would on a straight surface. An object will use less force to move upward in an inclined plane with a more gradual slope.

One of the most common applications of inclined planes is getting heavy objects into a truck using a ramp. Less force is required to get the object inside of the vehicle, the tradeoff being covering a longer distance.

Other types of inclined planes include:

- Wheelchair ramp

- Slide

- Slanted roof

Second Class Levers

In a second class lever, the load is located between the effort and the fulcrum.

In a second class lever, the load is located between the effort and the fulcrum. When the fulcrum is closer to the load, then less effort is needed to move the load (2020 Let’s Talk Science).

If the load is closer to the fulcrum than the effort, then less effort will be required to move the load. If the load is closer to the effort than the fulcrum, then more effort will be required to move the load. A wheelbarrow, a bottle opener, and an oar are examples of second class levers.

Second class levers are used in wheelbarrows (left), when going on tiptoes (centre) and when doing push-ups (Sources: MarkusHagenlocher via Wikimedia Commons, BruceBlaus via Wikimedia Commons and U.S. Navy via Wikimedia Commons).

Standard design features and benefits

- Two minute tool changeover

- Low maintenance polymer bearings

- Simple and accurate film-feed system with easy film route

- Maintenance friendly robust construction

- Accurate temperature and seal pressure control

- High accuracy tool alignment system provides a constantly accurate sealing and/or film-cutting relationship with the tray flange profile

- Simple design and operation

- Film snap detection

- ‘Auto Tool’ Touch of a button tool change system, automatically locates and connects tooling to machine functions including all MAP options

- All around seal and contoured film-cut with skeletal film rewind

- Automatic seal operation with accurate seal dwell time

- Self-centering tray guides

- Automatic film roll clamping

- Food industry approved hygienic construction and wash-down protection

- Full Category 3 guarding

- User friendly, menu-driven control panel with step-by-step prompts, error and status displays, and useful batch pack counter

- Recipe handling of machine settings

- Self diagnostic system

- Pendant mounted colour touch screen HMI control for full double-sided operation

- Recipe driven auto machine set-up for tool change

- On-screen data capture and trends with wireless connection option

- Pot crush avoidance system

- Active film tension

- QR conveyors with quick release belts for easy hygiene and maintenance

- Eseal – high-performance, high-precision, high-force, energy-efficient, electric seal system that boasts a massive increase in seal force

- Promotion – a high accuracy continuous motion tray infeed system, which increases production speed whilst reducing machine duty

GT1s Sealing Capacity

| No of trays | Length | Width | Depth | Diameter |

| One | 300mm | 670mm | 105mm | 300mm |

| Two | 300mm | 331mm | 105mm | 300mm |

| Three | 300mm | 212mm | 105mm | 212mm |

| Four | 300mm | 129mm | 105mm | 129mm |

| Five | 300mm | 98mm | 105mm | 98mm |

Is there a catch?

Lifting, cutting, chopping, moving, bending—machines like the ones we’ve explored up above make it easier to do all kinds of things by making forces bigger than you can normally create with your own body. At first sight, that sounds like it might open up the way to designing a machine that can give us something for nothing—maybe one that can make energy out of thin air, or a perpetual motion machine that runs forever.

In practice, the laws of physics are strict and if you make life easier for yourself in one way, you always make it harder in another to compensate. That’s the scientist’s way of saying “there’s no such thing as a free lunch,” and, in physics, it goes by the name of the law of conservation of energy (simply put: we can’t make energy appear magically out of nowhere). So whenever you have a machine that gives you more force, it doesn’t give you extra energy you didn’t have before. With a pulley, for example, ropes and wheels give you much more lifting force, but you have to heave them much further, so you use exactly the same amount of energy as you would have done before. You just use it more slowly, with less effort, so the lifting feels easier. In the same way, you can use a see-saw to lift a much heavier friend by sitting further from the balancing point than they are, but you have to move your legs much further to compensate. You get extra force, but no extra energy—and that’s the catch.

Artwork: A seesaw lets you create extra lifting force. The little red person can lift the big blue person by sitting further from the pivot point. That means they can lift a bigger force, but the catch is that they have to move their own body over a much bigger distance. This machine makes more force, but no more energy.

Screws

Photo: The spiral thread on a screw means it takes longer to drive

it into wood but—theoretically at least—you need less effort. The grooves also

help the screw to remain in place.

A screw bites into wood when you turn it around. You often read

science books that say a screw is “like

a ramp wrapped around in a circle”, which is pretty confusing and hard

to understand. But imagine you’re an ant and you want

to climb from the bottom of a screw to the top. If you climb vertically

up the outside, you go a relatively short distance but it takes an

awful lot

of climbing force. If you walk up the screw thread, winding around

and around, you’re really walking up a kind of spiral staircase—a ramp

wrapped around in a circle. Yes, you walk much further, but it’s a whole

lot easier. There’s another good thing about a screw too: because

the head is bigger than the shaft beneath it, a screw works

like a wheel (or lever): each time you turn the head, the sharpened

point beneath bites into the wood with greater force. The tapering

(cone-shaped) design makes it easier to drive in the screw.

Types

Simple machines reduce effort by either transferring a force, changing the direction of force, increasing the magnitude of force, or increasing the speed of force. The six different kinds are explained below.

Inclined Plane

The basic function of an inclined plane is to be able to either lift up or to lower an object. The surface of a plane is flat and when placed in a slanted manner it is known as an inclined plane. The principle on which it works is that you can move a large bulk for a long distance by applying slight force. Moving an object on an inclined or slanted surface is much easier than a straight surface.

Lever

The lever which is a bar-like rigid object moves against a turning point to move a third object. The turning point against which it moves is known as the fulcrum and the closer the object that needs to be moved is to the fulcrum, the easier it is to move the former. There are three types of levers; first-class lever, second class lever, and third class lever.

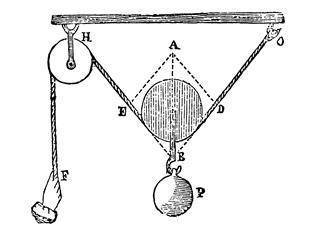

Pulley

In this simple machine one end of a cord is attached to the load that needs to be moved, placed over a wheel and as you pull on one side, according to the direction in which you exert force, you can move the load forward or backward. If you are looking for interactive simple machines, then try to make a model of a flag which is being hoisted. It uses the pulley system.

Screw

Many people consider screw to be a modified version of the inclined plane which differs in shape because of its helical appearance. It uses the principle of transfer of energy, converting rotational force into linear force in the process of performing a task. On one end of an inclined plane is a helical and on the other end is a provision that you can use to turn it. Screws are used to hold objects together and even to raise weights.

Wedge

It is made of two inclined planes and can move. The point of contact of the two inclined planes results in a sharp edge which can be used to cut and split objects and to hold them together. A wedge is shaped in such a manner that it is triangular in appearance. Examples of wedges that we use in daily life include forks, knives, and even our teeth.

Wheel and Axle

There are many games that you can play to explain the concept of the wheel and axle. You can use simple toys to explain the principle of this simple machine. The axle is the rod that is speared through the wheel to rotate it. The axle converts rotational force into linear force propelling the object forward.

Using lesson plans, you can come up with many ideas for simple machines that can be made easily. Most machines that we use nowadays have their basis in the principles on which these simple machines work.

Examples of Lever Simple Machine

1. Nut Cracker

A nutcracker is a prominent example of a second-class lever simple machine. Here, the fulcrum is located at one end of the machine, and the load or the nut, in this case, is placed in the middle. The force required to break the nut is applied to the end that is present opposite to the fulcrum.

2. Seesaw

Seesaws demonstrate the working of a first-class lever simple machine in the simplest possible way. Here, the fulcrum is located in the middle of an iron rod. The child sitting on one end of the beam acts as a load, while the child sitting on the opposite end applies the necessary force to move the load.

3. Scissors

The pivot along which the complete structure of a pair of scissors moves is located in the middle. The load, i.e., the paper or cloth is placed between the blades of the scissors at one end, whereas the user exerts mechanical force to the opposite end. The applied force gets transferred to the load through the fulcrum or the pivot, thereby causing the deformation of the load. Hence, a pair of scissors act as a first-class lever simple machine.

4. Plier

In terms of working, a plier is very much similar to that of a pair of scissors. It is yet another example of a first-class lever machine where the force is applied at one end, the load is placed at the opposite end, and the balance point is present in the middle.

5. Stapler

The balance point or the fulcrum of a stapler is present at one edge, whereas the force is applied to the opposite end. The load or the sheets of paper are placed in the middle. Hence, a stapler is a classic example of second-class lever simple machines.

6. Wheelbarrow

A wheelbarrow consists of a metallic container that is attached with handles at one end and a wheel at the other end. Here, the wheel acts as a fulcrum or the balance point, the load is placed in the middle, and the push force is applied to the handles. Therefore, the arrangement forms a second-class lever simple machine.

7. Human body

Various joints in the human body function on the basic principle of a lever simple machine. These body parts include the elbow joint, Achilles tendon, the joint between hummers and radius-ulna, the joint between the skull and the atlas vertebrae, etc.

8. Broom

When a broom is used for sweeping dirt, it acts as a third-class lever simple machine. This is because the load is present at the one end of the broom, i.e., on the brush side, the effort or the force is applied in the middle, and the pivot is located at the top.

9. Hammer

Hammer is yet another example of a third-class lever machine. The force is applied at the centre, the load or the reaction of the force is observed at the end, and the pivot is formed on the opposite end.

10. Balance Scale

A balance scale makes use of a pivot in the middle of a beam. On either side of the scale, containers are attached that are used to contain the standard and the unknown weights. This means that the fulcrum is present in the middle, whereas the load and effort are present on either side of the beam. Hence, a balance scale is one of the best examples of a first-class lever simple machine.

Inclined Planes

An inclined plane is exactly what its name says. It’s a plane that is inclined, or in other words, slanted. This simple machine connects a lower level to a higher level, making it easy to move objects. The slanting surface supports some weight of an object as it moving upwards, making it utilize less force. However, the object must move at a longer distance than it would on a straight surface. An object will use less force to move upward in an inclined plane with a more gradual slope.

One of the most common applications of inclined planes is getting heavy objects into a truck using a ramp. Less force is required to get the object inside of the vehicle, the tradeoff being covering a longer distance.

Other types of inclined planes include:

- Wheelchair ramp

- Slide

- Slanted roof

Machines are all around us!

That’s pretty much all there is to the science of simple machines.

Once you understand how machines work, you start seeing them

everywhere. Even your body is packed with machines. Your skeleton, for

example, is a collection of levers! Take a look around your home and

see how many more “simple machines” you can spot. You’ll be amazed how many there are!

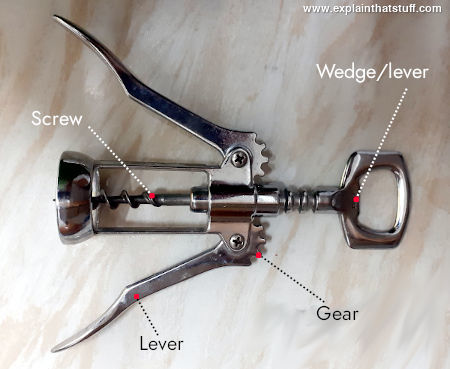

Photo: Lots of everyday tools contain several simple machines. I can count at least five on this corkscrew and bottle opener. The bottle opener on the right is a wedge. Once you’ve jammed it under a bottle-top, you use the rest of the (folded-up) corkscrew as a lever to jack the bottle open. The corkscrew contains another three simple machines. To open a wine bottle, you push the screw down into the cork. Then you use the levers to force the cork up and out of the bottle. The screw is linked to the levers by a kind of worm gear.

Second Class Levers

In a second class lever, the load is located between the effort and the fulcrum.

In a second class lever, the load is located between the effort and the fulcrum. When the fulcrum is closer to the load, then less effort is needed to move the load (2020 Let’s Talk Science).

If the load is closer to the fulcrum than the effort, then less effort will be required to move the load. If the load is closer to the effort than the fulcrum, then more effort will be required to move the load. A wheelbarrow, a bottle opener, and an oar are examples of second class levers.

Second class levers are used in wheelbarrows (left), when going on tiptoes (centre) and when doing push-ups (Sources: MarkusHagenlocher via Wikimedia Commons, BruceBlaus via Wikimedia Commons and U.S. Navy via Wikimedia Commons).

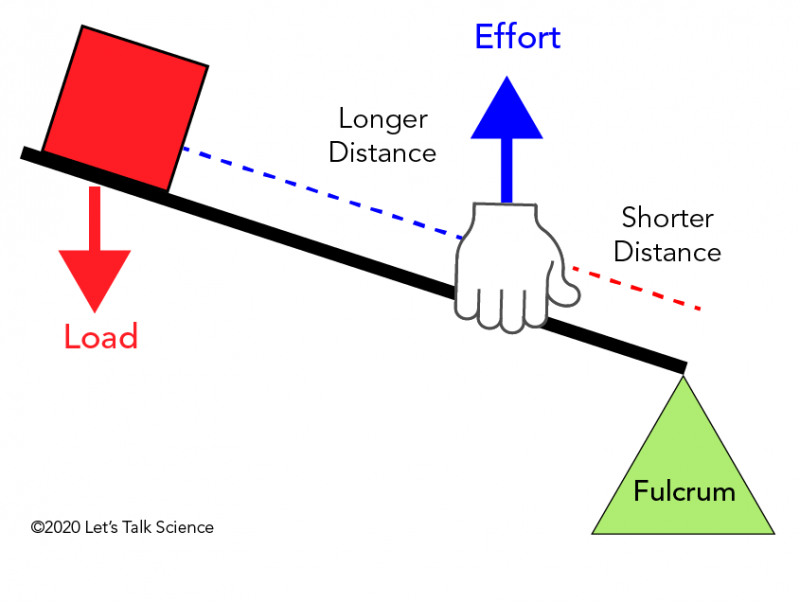

Third Class Levers

In a third class lever, the effort is located between the load and the fulcrum.

In a third class lever, the effort is located between the load and the fulcrum. If the fulcrum is closer to the load, then less effort is needed to move the load (2020 Let’s Talk Science).

If the fulcrum is closer to the load, then less effort is needed to move the load. If the fulcrum is closer to the effort, then the load will move a greater distance. A pair of tweezers, swinging a baseball bat or using your arm to lift something are examples of third class levers. These levers are useful for making precise movements.

Third class levers are used when swinging a tennis racquet (left), in staple-removers (centre) and when you lift objects using the muscles in your biceps (right) (Sources: Australian Paralympic Committee via Wikimedia Commons, Frank C. Müller via Wikimedia Commons and John Seb Barber via Wikimedia Commons).

Levers are very useful simple machines used for transferring force. You may not realize it, but you use levers every day!

Third Class Levers

In a third class lever, the effort is located between the load and the fulcrum.

In a third class lever, the effort is located between the load and the fulcrum. If the fulcrum is closer to the load, then less effort is needed to move the load (2020 Let’s Talk Science).

If the fulcrum is closer to the load, then less effort is needed to move the load. If the fulcrum is closer to the effort, then the load will move a greater distance. A pair of tweezers, swinging a baseball bat or using your arm to lift something are examples of third class levers. These levers are useful for making precise movements.

Third class levers are used when swinging a tennis racquet (left), in staple-removers (centre) and when you lift objects using the muscles in your biceps (right) (Sources: Australian Paralympic Committee via Wikimedia Commons, Frank C. Müller via Wikimedia Commons and John Seb Barber via Wikimedia Commons).

Levers are very useful simple machines used for transferring force. You may not realize it, but you use levers every day!

Find out more

Simple machines

- Making Machines with Levers by Chris Oxlade. Raintree, 2016. This is one of a series of six activity-driven books covering levers, wheels and axles, pulleys, ramps, screws, and springs. Ages 7–9.

- Simple Machines: Forces in Action by Buffy Silverman. Heinemann Library, 2016. A typical 48-page curriculum-based guide.

- The Kids’ Book of Simple Machines: Cool Projects and Activities That Make Science Fun by Kelly Doudna. Mighty Media, 2015. An activity-driven guide covering each of the simple machines in turn.

- How Machines Work: The Interactive Guide to Simple Machines and Mechanisms by Nick Arnold and Allan Sanders. Templar, 2011. A short book and hands-on experiment kit that introduces 12 simple machines for ages 7–9.

- The Science of Forces: Projects and Experiments with Forces and Machines by Steve Parker. Heinemann, 2005. A 32-page hands-on introduction to things like gears and ramps.